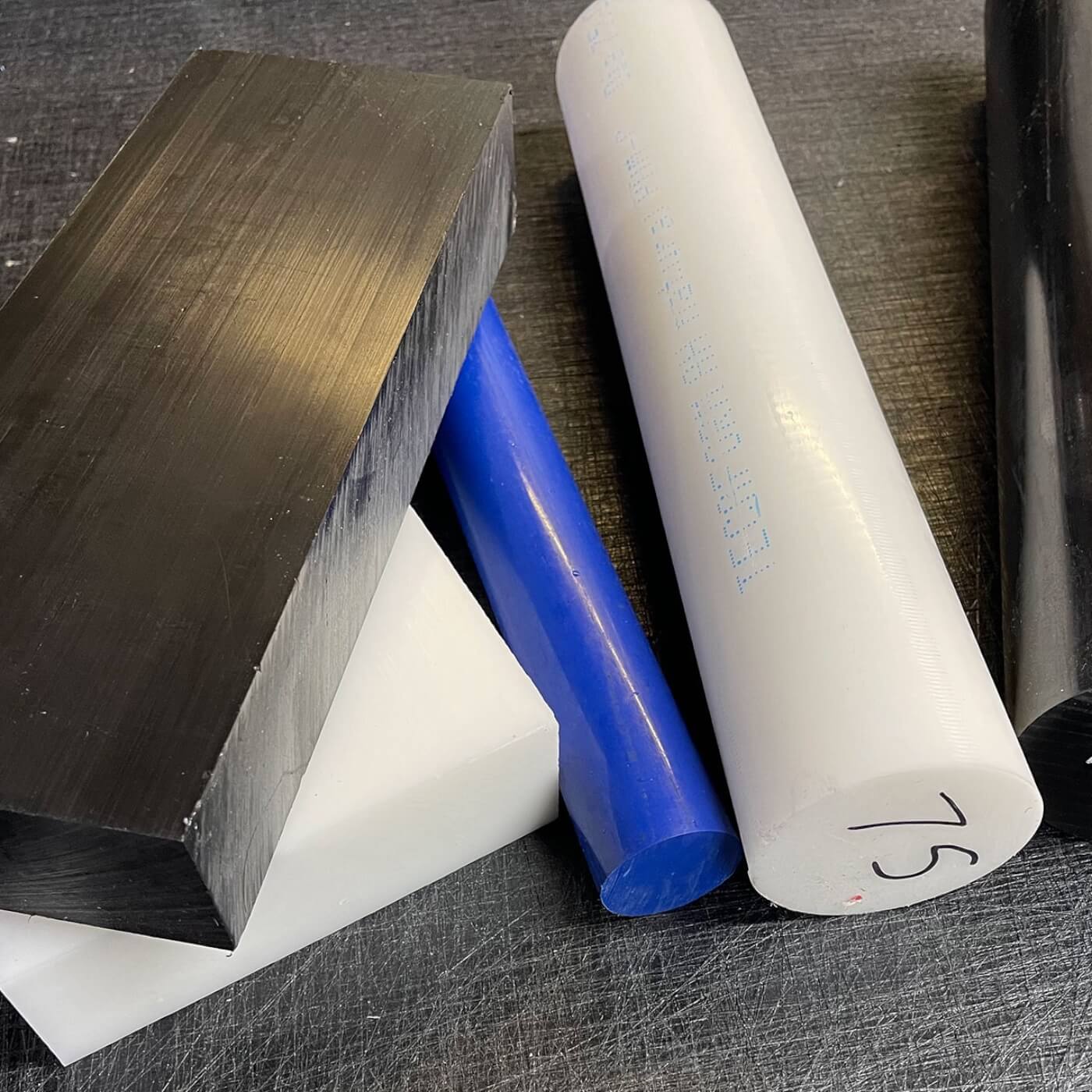

Choose Your Materials

Selecting the right plastic material for your product or application can be challenging. Fortunately, at WKH, we are experts in this field and are always on hand to help with any question or query. Below, we have provided an overview detailing everything you need to know about each material and its application.

| Requirement | Consider |

| Low Friction | |

| Sliding, slipping components | Nylons, Acetal, PTFE, UHMWE PE, PET (P) |

| Self-lubricating bearings | Nylons, pet (P) |

| Dimensional stability | Acetal, PET (P) and Glass Filled Grades |

| Wear resistance | UHMW PE, Cast Nylon 6 |

| Environment | |

| Chemical resistance | PVC, PP PVDF, HDPE, PEEK, PTFE |

| Sewarage / Waste / Water | WRAS Approved (Water Regulations Approval Scheme), Acetals, PVC |

| Electrical insulation | Thermoset Laminates, PVC, PTFE, PPE |

| ATEX / ESD avoidance | PC350 Antistatic Polycarbonate ,conductive PTFE Static dissipative Acetal / HDPE |

| Contact with foodstuff | Acetal, UHMW PE, PET (P), PP, PSU & PE |

| UV, Age hardening & radiation | High Performance, PEEK, PVDF, PCTFE |

| Model or prototype work | Acrylic. ABS, PVC |

| Loading | |

| Impact loads | Nylon 6 & 66, 1000 Grade UHMWPE, Epoxy Laminates, Polypropolene |

| Cyclical loading | Nylons, Acetal |

| Better resistance to creep | Glass Filled Grades, Thermoset Laminates |

| High continuous loading | PET(P), High Performance Plastic, PEEK |

| Temperature | |

| Low temperature impact strength | Nylons, UHMW PE, PVDF |

| Working temperatures >100°C | High Performance Plastics, PTFE, PEEK |

| Atex legislation/Directive | |

| Approved materials | Conductive plastic include- Carbon Filled PTFE, HDPE, Static Dissipative Acetal, Acrylic |

| FDA (Food and Drug Administration) | |

| and or Metal detectable. | UHMWPE, PTFE, Polypropylene, Metal Detectable Acetal |

Important Information: If your finished item or component is intended for standalone application, without support from hinges, clasps, braces, guide rails, etc., it is imperative to consider the potential effects of thermal movement, bowing, and twisting of plastics. These factors can significantly impact the performance and durability of your product.