Examples of

Components we've machined

Since 1992 we have manufactured tens of thousands of parts and components to the exact specification of our clients - here are a few examples of our exceptional capabilities.

Seal Housings

Seal housings, bag out ports & glove ports in HD500 ( High density polyethylene ) for pharmaceutical - powder containment industry.

Oil, Petrochemical and Subsea research industry

These components were made using high tolerance CNC machining. The customer required stab location plates, anchor block sleeves, protective covers guide stab annulus, attachment brackets, position indicators & protective sleeves. Made from Homopolymer / Copolymer Acetals, also Peek, Cast Nylons 66 and 6.

Intricate Plastic Components

Milled and turned plastic components using oil filled nylon, nylatron GSM and food grade green polyethylene & Virgin PTFE - all with great wearing properties suitable for conveyor and food processing industries.

ATEX Anti static PTFE static dissipative HDPE (Prolen 6000 EL) CNC machine routed / turned / milled components.

For applications in general mechanical engineering - sliding and conveyor elements - guide for belt drives - for high machine speeds in dry and dusty areas.

PTFE Bellows

We can produce PTFE Bellows and expansion joints to customer specification for filtration and drying equipment in the pharmaceutical industry.

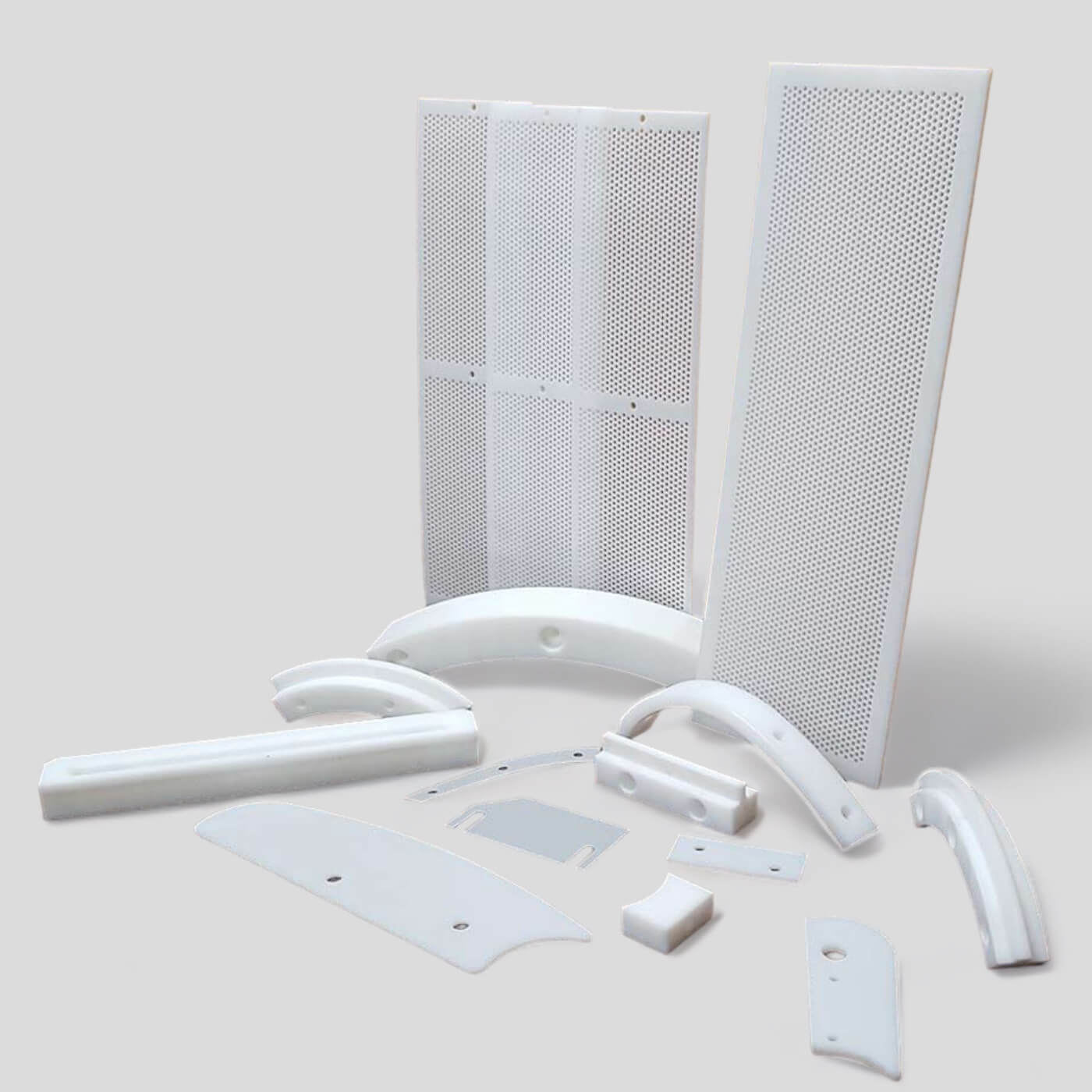

Plastics machined from HDPE, UHMWPE and Natural Polyethylene.

A selection of water and waste water flow screen plastics parts, including – perforated screen panels - travelling fine screens – curved chain guides – upper chain guides and packing links.

Plastics machined from HDPE / UHMWPE / Natural polyethylene which is FDA approved ( food and drug association ) And Kepital – WRAS approved ( water regulations advisory scheme).

Nylon / Polyamid / PA (Oil - Glass - Carbon Filled)

Gears, Bushes Jigs & Fixtures, Cams, Seal Rings and Pulleys.

Why choose the WKH Group?

There are many reasons why we stand out among our competitors, however here are a few reasons why we are the perfect match for you.

Highest Quality Service.

With over thirty years experience in plastic engineering across all industries, we bring the highest level of expertise to every project we undertake.

We collaborate closely with our clients and project engineers to ensure a thorough understanding of your requirements and specifications.

On Time, Every Time.

We understand the importance of time-sensitive projects which is why we prioritise responsiveness and proactiveness in our approach.

Our team is dedicated to swiftly addressing your needs and challenges, ensuring timely delivery without compromising on quality or precision.

Innovation & Investment.

At WKH Group, we are committed to innovation and investing in the latest technology, training and machinery to ensure we always provide the best solutions to our clients.

Our dedication and commitment to striving for perfection has kept us at the forefront of our industry for today, tomorrow and for decades to come.

BSEN ISO 9001:2015 Certified.

At the WKH Group we committed to quality excellence, holding certification to BSEN ISO 9001:2015 standards. Our dedication to maintaining the highest quality standards is reinforced by our investment in the latest technology and machinery.